Repairing Business Refrigeration Repair Work: Techniques for Quick and Effective Fixes

In the realm of commercial refrigeration, the requirement for swift and specific troubleshooting approaches is paramount. When a refrigeration system breakdowns, the repercussions can be costly and disruptive to business operations. Recognizing the usual problems that pester commercial refrigeration systems and having a toolkit of diagnostic strategies at hand can make all the distinction in promptly determining and correcting troubles. As we browse through the intricacies of troubleshooting business refrigeration fixing, we will reveal the essential approaches for solving issues efficiently, ensuring that services can preserve optimum air conditioning efficiency and decrease downtime.

Usual Industrial Refrigeration Issues

Commercial refrigeration systems commonly experience a variety of functional issues that can interrupt their performance and performance. One widespread issue is inappropriate temperature control, which can lead to food perishing and waste if not without delay attended to. This trouble might stem from issues with the thermostat, evaporator follower, or condenser coils, calling for extensive assessment to identify the origin reason. An additional typical issue is poor airflow, often brought on by clogs in the vents or a malfunctioning follower. Poor airflow can bring about temperature level disparities within the refrigerator or freezer, impacting the high quality and safety and security of kept items.

Furthermore, cooling agent leaks present a significant worry as they not only affect the air conditioning capacity of the system however likewise contribute to ecological injury. Regular cleansing and upkeep can help avoid this problem and prolong the life expectancy of the refrigeration system.

Analysis Devices and Strategies

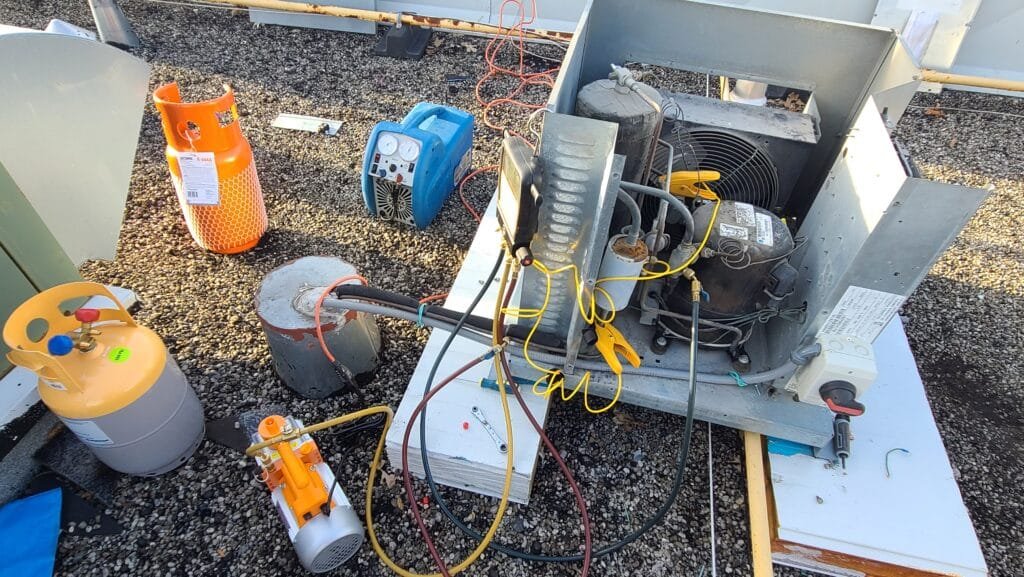

Efficient troubleshooting of commercial refrigeration systems relies heavily on utilizing specialized analysis tools and techniques to determine and resolve underlying problems successfully. One important analysis tool is the multimeter, which assists technicians measure voltage, current, and resistance in various elements such as compressors, electric motors, and thaw heaters. Thermostats are additionally essential for evaluating temperature level differentials throughout the system to identify prospective problems like cooling agent leakages or inappropriate air movement. Additionally, leak detection tools like electronic leak detectors or ultraviolet color packages are essential for situating refrigerant leakages that can cause system inadequacies.

Information loggers can be used to monitor system efficiency over time and identify trends that might indicate recurring issues. By integrating these analysis devices and methods, technicians can efficiently fix industrial refrigeration systems and give accurate and fast repair work, reducing downtime and making sure optimum system efficiency.

Quick Repairs for Refrigeration Problems

When confronted with refrigeration issues, specialists can implement quick solutions to address typical concerns swiftly and effectively. One typical quick solution is examining for an unclean condenser coil, which can create the system to run inefficiently. Cleaning up the condenser coil routinely can enhance the system's performance and stop getting too hot. An additional fast repair is image source ensuring that the refrigerator is not overwhelmed, as congestion can restrict air flow and bring about temperature variances. Readjusting the shelving to allow for correct air circulation can frequently settle this issue. Additionally, inspecting the door seals for any indications of wear or damages and changing them if required can assist maintain the stability of the seal and avoid air leaks. If the refrigeration device is not cooling appropriately, examining and changing the thermostat settings might give a quick option prior to even more thorough troubleshooting is called for. By applying these fast solutions, professionals can deal with typical refrigeration problems efficiently and keep industrial refrigeration systems running efficiently.

Preventative Maintenance Tips

Executing an aggressive maintenance schedule is crucial for making certain the durability and optimal efficiency of commercial refrigeration systems. Routine maintenance not just assists protect against pricey break downs but additionally makes certain that the equipment runs effectively, conserving energy and lowering overall operating expenses. Here are some preventative upkeep suggestions to maintain industrial refrigeration systems running efficiently:

Inspect and Replace Filters: Unclean filters can limit air movement, making the system work tougher and possibly triggering damage. Inspect and change filters on a regular basis to stop problems.

Inspect Seals and Gaskets: Leaky site here seals and gaskets can bring about temperature level changes and power wastefulness. Replacing and inspecting harmed seals can aid keep constant temperature levels.

Professional Support and Solutions

To preserve the ideal efficiency accomplished with regular preventative maintenance, seeking expert support and services for business refrigeration systems is crucial. Specialist technicians possess the competence and specialized expertise needed to identify and address complicated issues successfully. When dealing with difficult refrigeration problems, counting on specialist support can conserve both time and cash in the future.

Expert solutions provide advantages such as accessibility to advanced tools and tools, making certain that repair work are carried out effectively. Furthermore, technicians are educated to abide by sector laws and safety and security criteria, reducing the threat of accidents and making certain conformity with lawful needs.

Verdict

To conclude, troubleshooting industrial refrigeration fixing calls for a methodical technique to identifying common issues, using diagnostic devices and techniques, carrying out fast solutions, and prioritizing preventative upkeep. Professional assistance and services may be essential for even more complex troubles - commercial refrigeration repair. By adhering to these approaches, businesses can ensure their refrigeration systems run successfully and efficiently, lessening downtime and possible losses

Recognizing the This Site common problems that torment commercial refrigeration systems and having a toolkit of analysis methods at your disposal can make all the distinction in promptly recognizing and fixing troubles.Effective troubleshooting of business refrigeration systems depends greatly on making use of specialized analysis tools and methods to identify and deal with underlying problems effectively. By integrating these analysis devices and methods, technicians can effectively fix business refrigeration systems and give specific and fast repairs, reducing downtime and making sure optimum system efficiency.

By applying these quick solutions, technicians can attend to usual refrigeration troubles effectively and keep commercial refrigeration systems running smoothly.

Additionally, professional assistance can help prolong the lifespan of industrial refrigeration systems by identifying possible problems prior to they rise.